Peb muab cov khoom zoo

Cov khoom tshwj xeeb

-

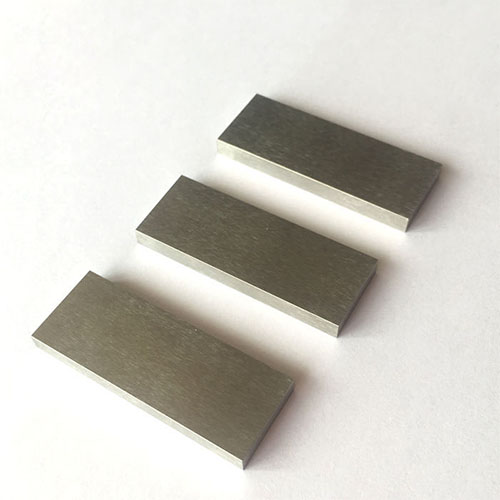

Molybdenum Copper Alloy, MoCu Alloy Sheet

Molybdenum tooj liab (MoCu) alloy yog cov khoom sib xyaw ntawm molybdenum thiab tooj liab uas muaj qhov hloov tau thermal expansion coefficient thiab thermal conductivity.Nws muaj qhov ntom ntom qis dua CTE piv nrog tooj liab tungsten.Yog li ntawd, molybdenum tooj liab alloy yog haum rau aerospace thiab lwm yam teb.

Molybdenum tooj liab alloy muab qhov zoo ntawm tooj liab thiab molybdenum, siab zog, siab tshwj xeeb lub ntiajteb txawj nqus, siab kub tsis kam, arc ablation tsis kam, zoo hluav taws xob conductivity thiab cua sov kev ua tau zoo, thiab kev ua haujlwm zoo.

-

Molybdenum Lanthanum (MoLa) Alloy Boat Tais

MoLa tais feem ntau yog siv rau cov hlau los yog sintering thiab annealing ntawm cov hlau tsis muaj hlau nyob rau hauv qhov chaw.Lawv raug siv rau nkoj sintering ntawm cov khoom siv hmoov xws li sintered ceramics rhiab heev.Nyob rau hauv tej qhov kub thiab txias, molybdenum lanthanum alloy yog yooj yim dua rau re-crystallized uas txhais tau tias nws tsis yooj yim rau deform thiab muaj lub neej ntev kev pab cuam.Molybdenum lanthanum tais yog exquisitely ua los ntawm siab ceev ntawm molybdenum, lanthanum daim hlau thiab zoo heev machining cov tswv yim.Feem ntau molybdenum lanthanum tais yog ua tiav los ntawm riveting thiab vuam.

-

Molybdenum Lanthanum (Mo-La) Alloy Hlau

Molybdenum Lanthanum (Mo-La) yog cov hlau ua los ntawm kev ntxiv Lanthanum Oxide rau hauv molybdenum.Molybdenum Lanthanum Hlau muaj cov khoom ntawm qhov kub thiab txias ntawm recrystallization, zoo dua ductility, thiab zoo heev hnav-resistant.Molybdenum (Mo) yog grey-hlau thiab muaj qhov thib peb-siab tshaj plaws melting point ntawm txhua lub caij ntawm tungsten thiab tantalum.High-temperature molybdenum xov hlau, tseem hu ua Mo-La alloy xov hlau, yog rau cov khoom siv kub kub (cov ntawv luam ntawv, txiv ntseej, thiab cov ntsia hlau), cov tuav lub teeb halogen, cov cua kub cua kub cua sov, thiab ua rau quartz thiab Hi-temp. cov ntaub ntawv ceramic, thiab lwm yam.

-

Molybdenum Lanthanum (MoLa) Alloy Sheets

MoLa alloys muaj zoo formability ntawm tag nrho cov qib thaum piv rau ntshiab molybdenum nyob rau hauv tib yam mob.Ntshiab molybdenum recrystallizes ntawm kwv yees li 1200 ° C thiab ua nkig heev nrog tsawg dua 1% elongation, uas ua rau nws tsis formable nyob rau hauv cov mob no.

MoLa alloys hauv phaj thiab daim ntawv ua tau zoo dua li cov ntshiab molybdenum thiab TZM rau kev siv kub.Qhov ntawd yog siab dua 1100 ° C rau molybdenum thiab siab dua 1500 ° C rau TZM.Qhov siab tshaj plaws qhov ntsuas kub rau MoLa yog 1900 ° C, vim qhov tso tawm ntawm lanthana hais tawm ntawm qhov chaw ntawm qhov kub siab tshaj 1900 ° C.

Qhov "tus nqi zoo tshaj" MoLa alloy yog ib qho uas muaj 0.6 wt% lanthana.Nws nthuav tawm qhov sib xyaw ua ke zoo tshaj plaws ntawm cov khoom.Tsawg lanthana MoLa alloy yog qhov sib npaug rau cov ntshiab Mo hauv qhov kub ntawm 1100 ° C - 1900 ° C.Qhov zoo ntawm high lanthana MoLa, zoo li superior creep resistance, tsuas yog paub, yog hais tias cov khoom yog recrystallized ua ntej siv nyob rau hauv high kub.

-

Kub Kub Molybdenum Lanthanum (MoLa) Al...

Molybdenum Lanthanum alloy (Mo-La alloy) yog oxide dispersion ntxiv dag zog rau alloy.Molybdenum Lanthanum (Mo-La) alloy yog tsim los ntawm kev ntxiv lanthanum oxide hauv molybdenum.Molybdenum Lanthanum alloy (Mo-La alloy) tseem hu ua lub ntiaj teb tsis tshua muaj molybdenum lossis La2O3 doped molybdenum lossis kub molybdenum.

Molybdenum Lanthanum (Mo-La) Alloy muaj cov khoom ntawm qhov kub thiab txias ntawm recrystallization, zoo ductility, thiab zoo heev hnav-resistant.Recrystallizing kub ntawm Mo-La alloy yog siab tshaj 1,500 degrees Celsius.

Molybdenum-lanthana (MoLa) alloys yog ib hom ODS molybdenum-muaj molybdenum thiab ib qho zoo heev ntawm lanthanum trioxide hais.Qhov me me ntawm lanthanum oxide hais (0.3 lossis 0.7 feem pua) muab cov molybdenum hu ua stacked fiber ntau.Qhov tshwj xeeb microstructure no ruaj khov ntawm txog 2000 ° C.

-

TZM Alloy Nozzle Tips for Hot Runner Systems

Molybdenum TZM - (Titanium-Zirconium-Molybdenum) alloy

Lub tshuab kub khiav yog ib qho kev sib dhos ntawm cov khoom siv cua sov uas siv rau hauv cov yas txhaj tshuaj pwm uas txhaj cov yas molten rau hauv cov kab noj hniav ntawm cov pwm, kom tau cov khoom zoo yas.Thiab nws feem ntau yog ua los ntawm nozzle, kub tswj, manifold thiab lwm yam.

Titanium zirconium molybdenum (TZM) kub khiav nozzle nrog kub tsis kam, siab zog, zoo corrosion kuj thiab lwm yam khoom zoo heev, yog dav siv nyob rau hauv txhua yam ntawm kub khiav nozzle ntau lawm.TZM nozzle yog ib qho tseem ceeb ntawm cov kub khiav, raws li lub nozzle nyob rau hauv daim ntawv zoo nws yuav muab faib ua ob hom loj, qhib rooj vag thiab lub qhov rooj valve.

-

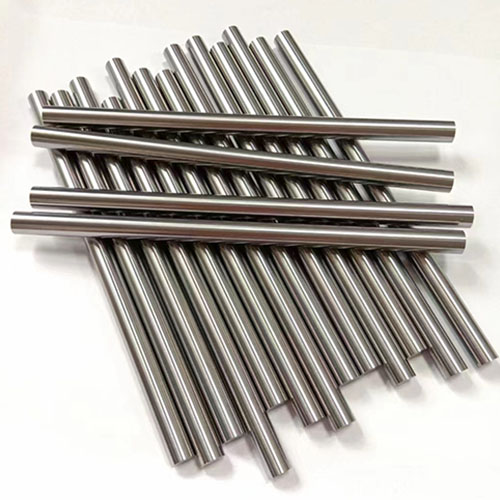

High Quality TZM Molybdenum Alloy Qws

TZM Molybdenum yog ib qho alloy ntawm 0.50% Titanium, 0.08% Zirconium, thiab 0.02% Carbon nrog qhov sib npaug Molybdenum.TZM Molybdenum yog tsim los ntawm P / M lossis Arc Cast technologies thiab muaj txiaj ntsig zoo vim nws lub zog siab / siab-kub siv, tshwj xeeb tshaj yog saum 2000F.

TZM Molybdenum muaj qhov kub siab dua recrystallization, siab zog, hardness, zoo ductility ntawm chav tsev kub, thiab siab kub dua unalloyed Molybdenum.TZM muab ob zaug lub zog ntawm cov ntshiab molybdenum ntawm qhov kub thiab txias tshaj 1300C.Lub recrystallization kub ntawm TZM yog kwv yees li 250 ° C, siab dua molybdenum, thiab nws muaj zoo weldability.Tsis tas li ntawd, TZM nthuav tawm cov thermal conductivity zoo, tsis tshua muaj vapor siab, thiab zoo corrosion kuj.

Zhaolixin tsim cov pa oxygen tsawg TZM alloy, qhov twg cov pa oxygen tuaj yeem txo qis dua 50ppm.Nrog rau cov pa oxygen tsawg thiab me me, cov khoom tawg tau zoo uas muaj cov txiaj ntsig zoo tshaj plaws.Peb cov TZM tsis tshua muaj oxygen muaj kev nkag siab zoo heev, siab dua recrystallization kub, thiab zoo dua lub zog kub.

-

High Quality Molybdenum Alloy Khoom TZM Allo ...

TZM (titanium, zirconium, molybdenum) Alloy Phaj

Molybdenum's prime alloy yog TZM.Cov hlau no muaj 99.2% min.99.5% max.Ntawm Mo, 0.50% Ti thiab 0.08% Zr nrog ib kab ntawm C rau carbide formations.TZM muab ob zaug lub zog ntawm ntshiab moly ntawm qhov kub thiab txias tshaj 1300′C.Lub recrystallization kub ntawm TZM yog kwv yees li 250′C siab tshaj moly thiab nws muaj zoo weldability.

Lub finer grain qauv ntawm TZM thiab tsim ntawm TiC thiab ZrC nyob rau hauv lub grain ciam teb ntawm lub moly inhibit grain loj hlob thiab muaj feem xyuam tsis ua hauj lwm ntawm lub hauv paus hlau raws li ib tug tshwm sim ntawm fractures raws li grain ciam teb.Qhov no kuj muab nws cov khoom zoo dua rau vuam.TZM raug nqi kwv yees li 25% ntau dua li cov ntshiab molybdenum thiab tsuas yog kwv yees li 5-10% ntau dua rau tshuab.Rau kev siv lub zog siab xws li foob pob hluav taws nozzles, cov khoom siv hluav taws xob ua kom sov, thiab forging tuag, nws tuaj yeem tsim nyog rau tus nqi sib txawv.

Cia siab rau peb, xaiv peb

Txog Peb

Cov lus piav qhia luv luv:

Luoyang Zhaolixin Tungsten & Molybdenum Materials Co., Ltd. yog nyob rau hauv Luoyang, lub qub peev ntawm cuaj dynasties.Nws yog ib lub tuam txhab tshwj xeeb hauv kev tsim khoom hnyav thiab ua tiav ntawm Tungsten, Molybdenum, Tantalum, Niobium thiab nws cov khoom siv hlau, nrog rau kev tsim cov tshuab nqus tsev thiab cov hom phiaj.Lub tuam txhab nyob hauv Luoyang City, Tuam Tshoj, uas yog qhov chaw yug ntawm Suav kab lis kev cai thiab ib qho ntawm Tuam Tshoj txoj kev lag luam tseem ceeb nrog lub peev xwm tsim muaj zog.Luoyang Zhaolixin muaj peev xwm ntawm sintering, kub isostatic nias, dov, forging, ntawv hlau, thiab machining ntawm Tungsten, Molybdenum, Tantalum thiab Niobium khoom.