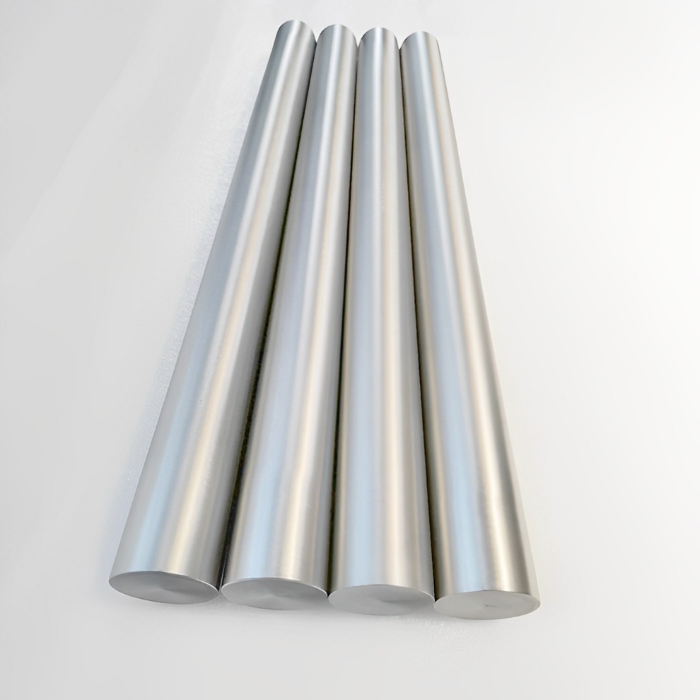

High Quality TZM Molybdenum Alloy Qws

Hom thiab Loj

TZM Alloy pas nrig kuj tseem muaj npe hu ua: TZM molybdenum alloy pas nrig, titanium-zirconium-molybdenum alloy pas nrig.

| Yam khoom npe | TZM Alloy Rod |

| Khoom siv | TZM Molybdenum |

| Specification | ASTM B387, HOM 364 |

| Loj | 4.0mm-100mm txoj kab uas hla x <2000mm L |

| Txheej txheem | Kev kos duab, swaging |

| Nto | Dub oxide, tshuaj ntxuav, Tiav tiav, sib tsoo |

Peb tseem tuaj yeem muab cov tshuab TZM Alloy qhov chaw rau ib daim duab kos.

Chemical Composition of TZM

Cov ntsiab lus tseem ceeb: Ti: 0.4-0.55%, Zr: 0.06-0.12%, C: 0.01-0.04%

| Lwm tus | O | Al | Fe | Mg | Ni | Si | N | Mo |

| Cov ntsiab lus (wt, %) | ≤ 0.03 | ≤ 0.01 | ≤ 0.002 | ≤ 0.002 | ≤ 0.002 | ≤ 0.002 | ≤ 0.002 | Bal. |

Qhov zoo ntawm TZM piv rau cov ntshiab molybdenum

- Tshaj 1100 ° C tensile lub zog yog li ob npaug ntawm cov molybdenum unalloyed

- Zoo dua creep kuj

- Siab dua recrystallization kub

- Cov khoom siv vuam zoo dua.

Nta

- Ceev:≥10.05g / cm3.

- Tensile zog:≥735MPa.

- Yield zog:≥685MPa.

- Elongation:≥10%.

- Hardness:HV 240-280.

Daim ntawv thov

TZM raug nqi kwv yees li 25% ntau dua li cov molybdenum ntshiab thiab tsuas yog kwv yees li 5-10% ntau dua rau lub tshuab.Rau kev siv lub zog siab xws li foob pob hluav taws nozzles, cov khoom siv hluav taws xob, thiab forging tuag, nws tuaj yeem tsim nyog tus nqi sib txawv.

Sau koj cov lus ntawm no thiab xa tuaj rau peb