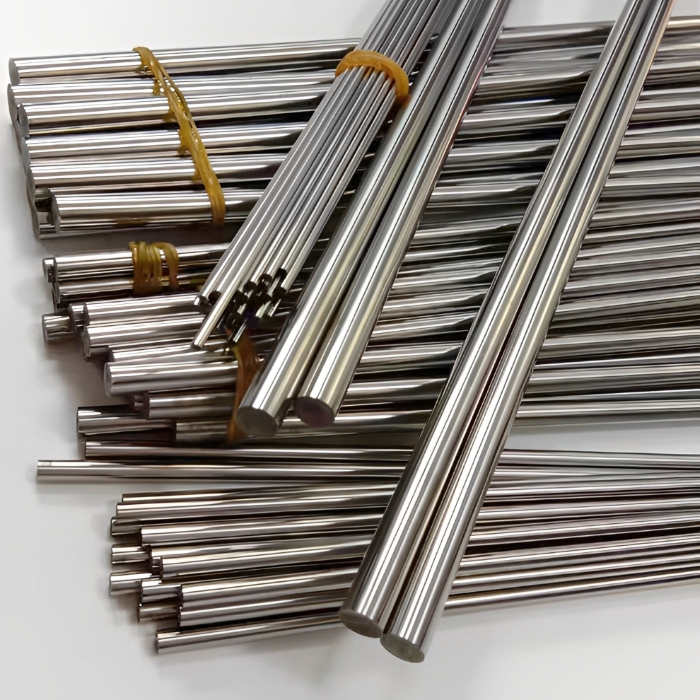

Kub Kub Molybdenum Lanthanum (MoLa) Alloy Qws

Hom thiab Loj

- Khoom siv:Molybdenum Lanthanum Alloy, La2O3: 0.3 ~ 0.7%

- Qhov Loj:txoj kab uas hla (4.0mm-100mm) x ntev (<2000mm)

- Txheej txheem:Kev kos duab, swaging

- Nto:Dub, tshuaj ntxuav, Sib tsoo

Nta

1. Qhov ceev ntawm peb molybdenum lanthanum rods yog los ntawm 9.8g / cm3mus txog 10.1 g / cm33;Qhov me me txoj kab uas hla, qhov ceev dua.

2. Molybdenum lanthanum pas nrig muaj cov yam ntxwv ntawm kub kub hardness, siab thermal conductivity, thiab tsis tshua muaj thermal expansion rau kub ua hauj lwm steels

3. Nws yog silvery-dawb, nyuaj, hloov hlau, uas muaj qhov thib yim-siab tshaj plaws melting point ntawm txhua lub caij;

4. Nws muaj qhov qis tshaj cua sov nthuav dav ntawm cov khoom lag luam siv hlau.

Daim ntawv thov

- Siv nyob rau hauv illumination, hluav taws xob lub tshuab nqus tsev twj.

- Siv rau lub raj tivthaiv hauv cathode-duab tshav yeeb nkab, lub zog semiconductor ntaus ntawv.

- Siv los tsim cov cuab yeej rau kev tsim cov iav thiab iav fiber ntau.

- Siv los tsim ib feem hauv lub teeb qhov muag teev, qhov kub thiab txias tiv thaiv, annealing Filament thiab Electrode, kub ntim thiab tivthaiv hauv microwave magnetron.

Molybdenum lanthanum rods tau dav siv rau cov cua kub hauv cov cua kub kub, electrodes, screws, rabbles hauv lub ntiaj teb tsis tshua muaj kev lag luam smelting, cua sov electrodes hauv iav kev lag luam thiab kev txhawb nqa ntawm lub teeb hauv kev lag luam teeb pom kev zoo, thiab lwm yam.