Ntshiab Molybdenum Qws, Molybdenum Bar, Molybdenum Electrode

Specifications

Hom thiab Loj:

| Hom | Swaged Rods | Straightened Rods tom qab kos | Av los yog machined rods muaj |

| Loj | Φ2.4 ~ 120 hli | F0.8 ~ 3.2 hli |

Tshuaj muaj pes tsawg leeg:

| Mo Cov ntsiab lus | Tag Nrho Cov Ntsiab Lus ntawm Lwm Yam | Txhua Element Cov ntsiab lus |

| ≥99.95% | ≤ 0.05% | ≤0.01% |

Daim ntawv thov

- Haum rau tsim ion implantation qhov chaw.

- Rau kev tsim hluav taws xob lub teeb qhov chaw thiab cov khoom siv hluav taws xob lub tshuab nqus tsev.

- Rau kev tsim cov khoom cua sov thiab cov khoom siv refractory nyob rau hauv qhov cub kub.

- Siv hauv kev lag luam iav thiab iav fiber ntau, nws tuaj yeem ua lub neej ntev hauv cov iav melted ntawm 1300 ℃.

- Siv raws li electrodes nyob rau hauv lub teb ntawm tsawg ntiaj teb hlau kev lag luam.

Khoom siv tes ua

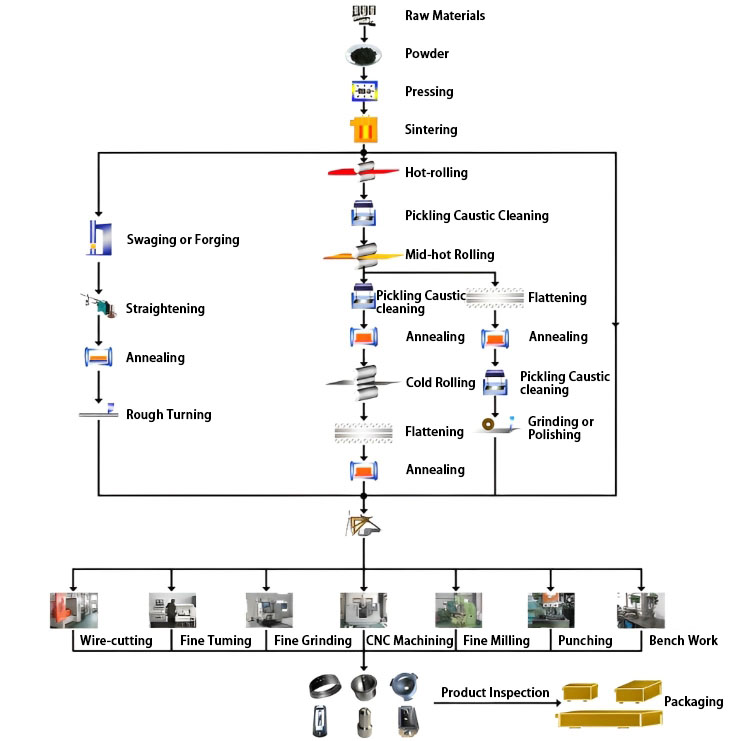

Raw Khoom:Pib los ntawm cov khoom siv raw, peb xaiv cov khoom zoo raw khoom, uas yog qhov tseem ceeb hauv kev ruaj khov thiab sib xws ntawm cov khoom.Txheeb xyuas cov khoom sib txawv ntawm cov khoom siv raw thiab kos tus lej batch.Thiab txhua batch ntawm raw cov ntaub ntawv yuav tsum tau kuaj, soj ntsuam thiab archived.Xyuas kom cov traceability ntawm txhua yam khoom tiav thiab txuas ntxiv txhim kho cov khoom zoo.

Hmoov:Kev tswj ntawm cov txheej txheem milling ntawm Zhaolinxin Cov khoom siv hlau yog qhov tseeb heev, nrog ntau lub tshuab sib xyaw loj thiab kev vibration platform los xyuas kom meej tias cov ntaub ntawv hauv cov txheej txheem pulverizing thiab sib tov tuaj yeem sib xyaw ua ke thiab sib npaug sib npaug, txhawm rau ua kom lub koom haum sab hauv sib xws ntawm cov khoom.

Nias:Nyob rau hauv cov txheej txheem ntawm cov hmoov compacting, cov hmoov yog nias los ntawm isostatic nias cov cuab yeej ua kom nws cov qauv sab hauv tsis sib xws thiab ntom.Zhaolixin muaj cov pwm zoo heev, thiab tseem muaj cov khoom siv isostatic nias kom tau raws li cov khoom lag luam loj loj.

Sintering:Hauv cov hmoov hlau metallurgy, tom qab cov hmoov hlau yog tsim los ntawm isostatic nias, nws yog rhuab ntawm qhov kub thiab txias qis tshaj qhov melting point ntawm lub ntsiab Cheebtsam kom cov khoom sib txuas, thiaj li txhim kho kev ua tau zoo ntawm cov khoom, uas yog hu ua sintering.Tom qab cov hmoov tsim, lub cev ntom ntom tau los ntawm sintering yog ib hom khoom siv polycrystalline.Cov txheej txheem sintering ncaj qha cuam tshuam rau cov qoob loo loj, qhov pore loj thiab cov qoob loo ciam teb thiab faib rau hauv microstructure, uas yog cov txheej txheem tseem ceeb ntawm cov hmoov metallurgy.

Forging:Cov txheej txheem FORTKev tswj kom raug ntawm tus nqi ua thiab forging kub ntawm tungsten thiab molybdenum cov ntaub ntawv yog qhov tseem ceeb rau kev ua tau zoo ntawm Zhaolixin tungsten thiab molybdenum cov ntaub ntawv.Ib txoj kev ua haujlwm ntawm kev siv lub tshuab forging los siv lub siab rau cov hlau dawb paug rau plastically deform nws kom tau txais ib qho forging nrog qee yam khoom siv, qee yam duab thiab qhov loj me.

Rolling:Cov txheej txheem dov ua rau cov khoom siv hlau tsim cov yas txuas ntxiv deformation nyob rau hauv lub siab ntawm cov rotating yob, thiab tau txais cov seem uas yuav tsum tau ua thiab cov khoom.Nrog advanced tungsten thiab molybdenum txias thiab kub dov tshuab thiab khoom siv, los ntawm tungsten thiab molybdenum hlau dawb paug mus rau zus tau tej cov tungsten thiab molybdenum ntawv ci, Zhaolixinguarantees koj ntau lawm ntau lawm technology thiab superior hlau zog.

Kev kho cua sov:Tom qab cov txheej txheem forging thiab dov, cov khoom raug rau cov txheej txheem kev kho cua sov kom tshem tawm cov kev ntxhov siab sab hauv ntawm cov khoom, muab kev ua si rau cov khoom siv, thiab ua kom cov khoom yooj yim rau kev ua haujlwm tom ntej.Zhaolixin muaj ntau lub tshuab nqus tsev rauv thiab kho cua sov hydrogen rauv kom tau raws li kev xa khoom sai ntawm kev txiav txim ntau lawm.

Machining:Cov khoom ntawm Zhaolixin tau ua tiav kev kho cua sov, thiab tom qab ntawd ua tiav rau hauv ntau qhov ntau thiab tsawg los ntawm kev siv tshuab xws li tig, milling, txiav, sib tsoo, thiab lwm yam, thiab xyuas kom meej tias lub koom haum sab hauv ntawm tungsten thiab molybdenum cov ntaub ntawv nruj, tsis muaj kev ntxhov siab. thiab qhov tsis muaj qhov, uas tuaj yeem ua tau raws li cov neeg siv khoom xav tau.

Quality Assurance:Kev tshuaj xyuas zoo thiab kev tswj xyuas yuav raug ua los ntawm cov khoom siv raw thiab rau txhua kauj ruam ntawm kev tsim khoom, txhawm rau kom tsis tu ncua kom zoo txhua yam khoom.Nyob rau tib lub sijhawm, thaum cov khoom tiav raug xa tawm los ntawm lub tsev rau khoom, cov tsos, qhov loj me thiab cov koom haum sab hauv ntawm cov khoom raug kuaj ib los ntawm ib qho.Yog li ntawd, kev ruaj ntseg thiab sib xws ntawm cov khoom yog qhov tshwj xeeb.