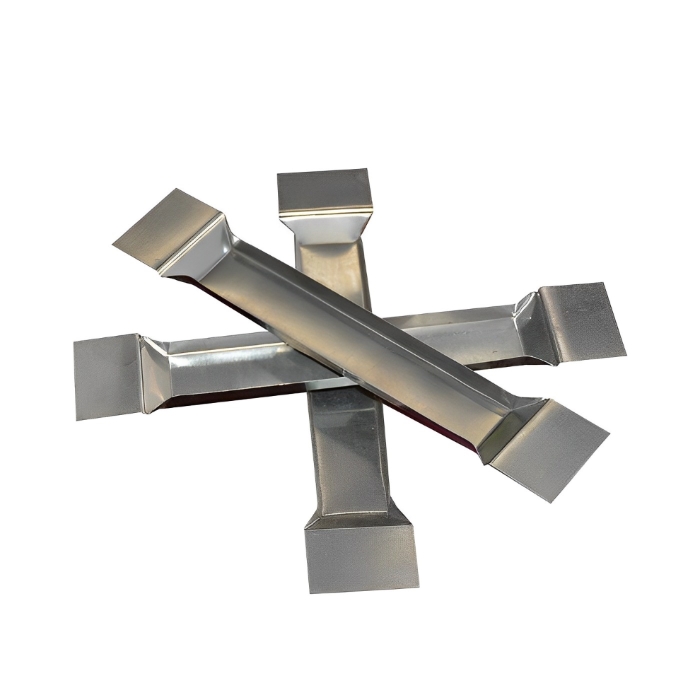

Customized Tungsten Boats Rau Lub Tshuab Nqus Tsev

Hom thiab Loj

| cov ntsiab lus | qhov loj (mm) | Qhov ntev (mm) | Qhov tob (mm) |

| lub nkoj tungsten | 0.2 * 10 * 100 hli | 50 | 2 |

| 0.2 * 15 * 100 hli | 50 | 7 | |

| 0.2 * 25 * 118 hli | 80 | 10 | |

| 0.3 * 10 * 100 hli | 50 | 2 | |

| 0.3 * 12 * 100 hli | 50 | 2 | |

| 0.3 * 15 * 100 hli | 50 | 7 | |

| 0.3 * 18 * 120 hli | 70 | 3 | |

| Nco tseg: Qhov loj me tshwj xeeb tuaj yeem kho raws li cov neeg siv khoom xav tau | |||

Nta

Tungsten nkoj yog siv rau lub tshuab nqus tsev evaporator ntawm cov ntaub ntawv granular.Cov nkoj tungsten kuj tseem siv tau los ua kom evaporate nyias, luv xov hlau lossis cov xov hlau ntub dej.Tungsten evaporation nkoj yog tsim rau kev sim lossis ua qauv ua haujlwm hauv cov evaporation me me, zoo li lub tswb nrov.Raws li lub nkoj tshwj xeeb thiab zoo li lub thawv, lub nkoj tungsten yog dav siv nyob rau hauv electron ray spraying, sintering thiab annealing nyob rau hauv lub tshuab nqus tsev txheej.

Tungsten evaporation nkoj yog tsim los ntawm cov kab tshwj xeeb;peb lub tuam txhab tuaj yeem muab cov neeg siv khoom nrog cov khoom zoo.Peb lav cov tungsten raw cov ntaub ntawv uas peb siv yog high-purity.Advanced thev naus laus zis thiab kev kho tshwj xeeb yog siv rau hauv kev kho deg ntawm peb cov khoom.Peb lub tuam txhab tuaj yeem tsim lub nkoj tungsten rau lub tshuab nqus tsev vacuum raws li cov neeg siv khoom kos duab.

Daim ntawv thov

Tungsten nkoj tuaj yeem siv rau hauv kev lag luam teeb, kev lag luam hluav taws xob, kev lag luam tub rog, kev lag luam semiconductor: txheej, sintering precision ceramics, capacitor sintering, tswb thawv, electron beam txau.X-ray diagnostic phiaj, crucible, cua sov caij, X-ray hluav taws xob tiv thaiv, sputtering phiaj, electrode, semiconductor puag phaj, thiab electron tube tivthaiv, emission cathode ntawm electron beam evaporation, thiab cathode thiab anode ntawm ion implanter.